Technology peripherals

Technology peripherals

AI

AI

Audi Is Quietly Building The Most Advanced AI Factory In The Auto Industry

Audi Is Quietly Building The Most Advanced AI Factory In The Auto Industry

Audi Is Quietly Building The Most Advanced AI Factory In The Auto Industry

Jun 04, 2025 am 11:09 AM

During a briefing on June 2, the German automaker disclosed that over 100 AI projects are currently operational or in development across its global production network. These systems are actively involved in tasks ranging from checking welds and predicting equipment malfunctions to improving logistics and aiding human workers in activities such as managing parts flow and process simulation.

"Artificial intelligence is the key factor transforming our industry," stated Gerd Walker, Audi’s Board Member for Production and Logistics. "By strategically applying it, we are establishing a production setting that is not only more efficient and economical but also adheres to the strictest quality benchmarks."

Audi notes that these AI initiatives are not merely small-scale trials or tech-centric demonstrations. Instead, Audi has integrated AI throughout its factories to influence decision-making and production on a large scale.

AI as a Core Component of Manufacturing Infrastructure

What sets Audi apart in its approach to AI is the depth of integration. Most manufacturers have experimented with AI in limited scenarios, such as visual inspections, coordinating robotic assembly, supply chain predictions, or predictive analytics. Audi is surpassing these isolated applications by adopting a comprehensive AI strategy within the production environment that can adjust dynamically.

Its computer vision systems now examine surface finishes and structural welds with exceptional consistency and precision. Its "Weld Splatter Detection" (WSD) application employs AI to spot potential weld splatter on vehicle underbodies, while its IRIS tool utilizes computer vision-equipped cameras to confirm if labels containing the correct technical data in the appropriate language are properly affixed to the vehicle.

Generative AI models simulate factory layouts and assist in planning production modifications prior to implementation. Predictive maintenance tools, trained on vast amounts of machine and sensor data, identify potential issues days or even weeks before they arise.

The company’s "Tender Toucan" tool evaluates bids during the procurement process, using specifications to compile a list of requirements, then utilizing that information to locate the pertinent sections in the bids and assess the extent to which they are met. Staff members have reported saving up to 30% of their time.

From Data Swamps to Adaptive Systems

While AI technology garners much of the focus, the true innovation at Audi lies in its data usage. Audi’s facilities produce massive amounts of data daily, with multiple petabytes generated across sensors, robotics, and logistics systems. Instead of treating this as unused digital waste that accumulates in the organization's data "swamp", Audi employs it to train machine learning models that continually enhance production operations.

In certain facilities, these models have reduced unexpected machine downtime by almost 30%. In others, they've shortened assembly times by fine-tuning the timing and manner in which components arrive at specific stations.

"Artificial intelligence allows us to exploit our vast data resources in production more extensively and accelerates our 360factory’s transformation into a data-driven factory," said Walker.

Audi explains that the 360factory represents the company’s production strategy for fully interconnected, innovative, and sustainable manufacturing.

Smart Factories That Learn on the Job

Audi’s efforts reflect a broader shift in how manufacturers perceive production. Rather than viewing factories as fixed systems with rigid processes, companies like Audi are converting them into adaptable environments, more akin to living organisms than static machinery.

AI is aiding these manufacturers in handling supply chain disruptions, swiftly reconfiguring workflows, and planning for increasingly personalized vehicle production runs, particularly in a challenging global political and economic climate.

Other carmakers are following suit. Porsche has implemented AI to oversee welding quality in Leipzig. BMW has expanded AI to final inspection stages. Tesla has incorporated AI into robot programming and vision systems. Although few have integrated AI into the entire production lifecycle as extensively as Audi, it is evident that this is the direction the industry is moving toward.

The Shift: From Feature to Fabric

Most current corporate AI implementations follow a predictable model: one tool per task. Audi’s strategy illustrates what occurs when AI becomes part of the operational framework.

This difference is significant. It implies a future where AI doesn’t just "assist," but instead serves as the connecting element binding systems, people, and decisions. Ponder less about dashboards and more about real-time optimization occurring silently in the background.

This approach also mirrors a shift in AI maturity. The discussion is transitioning from capability to utility. Companies like Audi are demonstrating that what matters most now isn’t what AI can do, but how it can alter the way an organization functions.

The above is the detailed content of Audi Is Quietly Building The Most Advanced AI Factory In The Auto Industry. For more information, please follow other related articles on the PHP Chinese website!

Hot AI Tools

Undress AI Tool

Undress images for free

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Clothoff.io

AI clothes remover

Video Face Swap

Swap faces in any video effortlessly with our completely free AI face swap tool!

Hot Article

Hot Tools

Notepad++7.3.1

Easy-to-use and free code editor

SublimeText3 Chinese version

Chinese version, very easy to use

Zend Studio 13.0.1

Powerful PHP integrated development environment

Dreamweaver CS6

Visual web development tools

SublimeText3 Mac version

God-level code editing software (SublimeText3)

Hot Topics

AI Investor Stuck At A Standstill? 3 Strategic Paths To Buy, Build, Or Partner With AI Vendors

Jul 02, 2025 am 11:13 AM

AI Investor Stuck At A Standstill? 3 Strategic Paths To Buy, Build, Or Partner With AI Vendors

Jul 02, 2025 am 11:13 AM

Investing is booming, but capital alone isn’t enough. With valuations rising and distinctiveness fading, investors in AI-focused venture funds must make a key decision: Buy, build, or partner to gain an edge? Here’s how to evaluate each option—and pr

AGI And AI Superintelligence Are Going To Sharply Hit The Human Ceiling Assumption Barrier

Jul 04, 2025 am 11:10 AM

AGI And AI Superintelligence Are Going To Sharply Hit The Human Ceiling Assumption Barrier

Jul 04, 2025 am 11:10 AM

Let’s talk about it. This analysis of an innovative AI breakthrough is part of my ongoing Forbes column coverage on the latest in AI, including identifying and explaining various impactful AI complexities (see the link here). Heading Toward AGI And

Kimi K2: The Most Powerful Open-Source Agentic Model

Jul 12, 2025 am 09:16 AM

Kimi K2: The Most Powerful Open-Source Agentic Model

Jul 12, 2025 am 09:16 AM

Remember the flood of open-source Chinese models that disrupted the GenAI industry earlier this year? While DeepSeek took most of the headlines, Kimi K1.5 was one of the prominent names in the list. And the model was quite cool.

Future Forecasting A Massive Intelligence Explosion On The Path From AI To AGI

Jul 02, 2025 am 11:19 AM

Future Forecasting A Massive Intelligence Explosion On The Path From AI To AGI

Jul 02, 2025 am 11:19 AM

Let’s talk about it. This analysis of an innovative AI breakthrough is part of my ongoing Forbes column coverage on the latest in AI, including identifying and explaining various impactful AI complexities (see the link here). For those readers who h

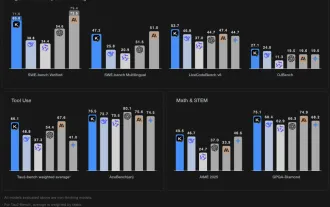

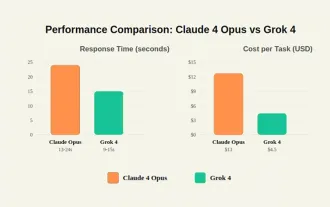

Grok 4 vs Claude 4: Which is Better?

Jul 12, 2025 am 09:37 AM

Grok 4 vs Claude 4: Which is Better?

Jul 12, 2025 am 09:37 AM

By mid-2025, the AI “arms race” is heating up, and xAI and Anthropic have both released their flagship models, Grok 4 and Claude 4. These two models are at opposite ends of the design philosophy and deployment platform, yet they

Chain Of Thought For Reasoning Models Might Not Work Out Long-Term

Jul 02, 2025 am 11:18 AM

Chain Of Thought For Reasoning Models Might Not Work Out Long-Term

Jul 02, 2025 am 11:18 AM

For example, if you ask a model a question like: “what does (X) person do at (X) company?” you may see a reasoning chain that looks something like this, assuming the system knows how to retrieve the necessary information:Locating details about the co

This Startup Built A Hospital In India To Test Its AI Software

Jul 02, 2025 am 11:14 AM

This Startup Built A Hospital In India To Test Its AI Software

Jul 02, 2025 am 11:14 AM

Clinical trials are an enormous bottleneck in drug development, and Kim and Reddy thought the AI-enabled software they’d been building at Pi Health could help do them faster and cheaper by expanding the pool of potentially eligible patients. But the

Senate Kills 10-Year State-Level AI Ban Tucked In Trump's Budget Bill

Jul 02, 2025 am 11:16 AM

Senate Kills 10-Year State-Level AI Ban Tucked In Trump's Budget Bill

Jul 02, 2025 am 11:16 AM

The Senate voted 99-1 Tuesday morning to kill the moratorium after a last-minute uproar from advocacy groups, lawmakers and tens of thousands of Americans who saw it as a dangerous overreach. They didn’t stay quiet. The Senate listened.States Keep Th